The spread of wine

Since ancient times, wine has evolved as part of Italian and European tradition, culture and diet. Brought at first from the East, the vine came in Italy in the middle of the second millennium B.C. thanks to the Aegean merchants and the new settlements of the Greek colonists, and then spread with the expansion of the Etruscan civilization in central and northern Italy.

The wine production was widespread and definitively affirmed in Italy and Europe with the expansion of the Roman empire in the Mediterranean, when many big and still living wine regions where planted. Wine production was already a meticulous practice that favored the development of different varieties of grapes and different cultivation techniques.

The wine production was widespread and definitively affirmed in Italy and Europe with the expansion of the Roman empire in the Mediterranean, when many big and still living wine regions where planted. Wine production was already a meticulous practice that favored the development of different varieties of grapes and different cultivation techniques.

Wine and christianity

Wine and christianity

From beer to wine

New forms of agriculture were invented and experts started studying vinification on scientific basis and writing manuals about wine-making. In the last 150 years, wine-making has been revolutionized as art and science. The introduction of harvesting machines allowed to increase the productivity of vineyards. Although wine industry has to satisfy the demand, which is still growing, while safeguarding the individual character of the different wines, technology contributes to ensure an adequate supply of high quality wines.

Determining the harvest time

Controlling the ripening of the grapes is essential to determine the harvest time according to the wine that you want or can get.

At the end of veraison (when the grapes pass from the herbaceous to the ripening phase, resulting in yellow or red skin coloring), it is advised to perform two weekly checks to determine some important factors of the ripening process.

In doing so, you can perform a sampling using bunches of clusters or grapes always taken from the same screws or in the same vineyard area. Proceed to the squeezing of the grape sample and, using the meter or refractometer, determine:

1) the gradient of sugary.

2) total acidity and Ph.

Light white wines

- Harvest grapes before full ripening.

- Total acidity greater than 7 gr / liter.

- Sugar lower than 17 ° Babo.

Structured white wines

- Wait for the full ripening of the grapes.

- Doughy acidity between 5 and 6 grams per liter.

- Sugar content above 20° Babo

Light red wines

- Harvest grapes before full ripening.

- Total acidity above 6.5 grams / liter.

- Sugar lower than 18 ° Babo.

Red wines for aging

- Wait for the full ripening of the grapes.

- Total acidity greater than 5 gr / liter

- Very low acidity and high Ph values in red grapes can cause fermentative problems.

Enological products for winemaking

These products, used during vinification, have the purpose of preventing alterations of the must, keep fermentation in check and accelerating the decantation and extraction processes.

Sulfuric anhydride and its derivatives:

- Useful to select the yeasts by favoring those with the best fermentative characteristics

- Prevents bacterial alterations when spoiled grapes are vinified

- Avoids unwanted oxidation of the musts in the early stages

Selected yeast

- Ensures regular fermentation

- Enhances the grape unique characteristics

Pectolitic enzymes for white musts

- Separate the clear part of the must from the solid one (dregs).

Enzymes for red musts

- Extract the color from the grapes skins.

Fermenting agents

- The source of yeast feeding.

Tannins

- Stabilize the color of red wines

- Prevent oxidation of the must in case of defective grapes.

Vinification of early grapes

The vinification of early grapes (Chardonnay, Pinot, Sauvignon, etc.) occurs by fermenting only the must without maceration of the solid parts of the bunch. Below is a brief and simple guide for perfect processing thanks to the use of GRIFO nameplate machines.

1) Quickly separate the must from the skins to avoid the extraction of tannins.

1) Quickly separate the must from the skins to avoid the extraction of tannins.

2) When squeezing, to empty the pomace, separate the “flower must” from the last fraction of the crushing (pressing). The “must flower” represents 60 to 65% of the weight of the bunch. Potassium metabisulphite can be added before pressing or immediately after in doses of between 12 and 16 grams per quintal of grapes.

3) Cool the must immediately and bring it to a temperature below 18-20°

4) Clarify the “flower must” separating the solid part composed of pieces of peel and parts of the pulp that form a deposit (“cleansing dregs”). For this operation, use the enzyme for the clarification of white musts in doses of 2 to 5 grams per hectolitre, melting it in a small fraction of must and then adding it to the whole mass.

5) At this point it’s time for the fermentation. Spontaneous fermentation can be chosen, otherwise the fermentation can be facilitated by adding 20 to 30 grams per hectolitre of selected yeast. It is important to keep the temperature between 16 and 20°, especially in the early days of fermentation.

At the end of the fermentation, make the first transfer without adding sulfur dioxide products, which, if desired, should be added instead on the second transfer 5-6 days after the first.

We design a small wine cellar to produce up to 10 hectoliters of wine

Our ambition is to offer concrete and professional help to all those who wish to produce their own wine and, thanks to our manual or electric oenological machines, rediscover the ancient art of grape processing. We are aware of your needs and we can plan on offering you what you need. Here are, for example, some tips on how to design a small winery.

1- Subdivision of the cellar into working areas

1- Subdivision of the cellar into working areas

AREA FOR GRAPE PRESSING AND VINIFICATION: choose an outside area, preferably under a porch. It must be an easily accessible area and convenient to clean. The floor should be smooth or in concrete with a good slope to facilitate sgrond and water collection from washing tanks. If the fermentation area is internal, make sure the room is well ventilated to avoid carbon dioxide stagnation that may be dangerous.

2- Wine-making equipment

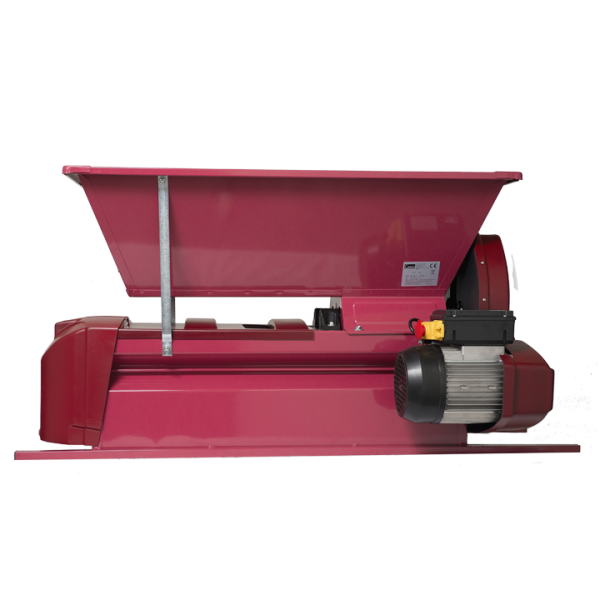

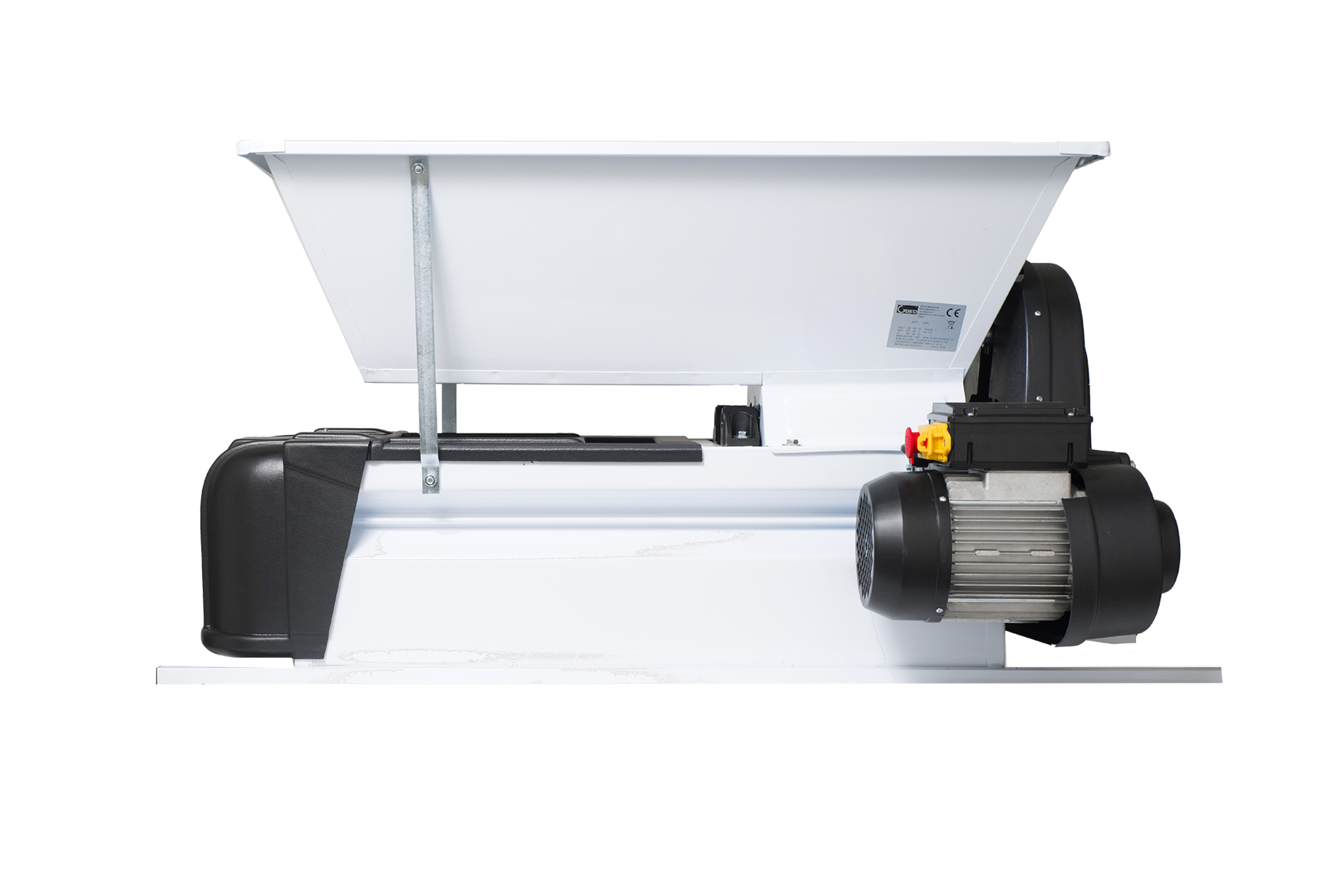

CRUCHER: crushes the grapes through the compression exerted by the rollers that rotate in opposite directions. Used primarily for the pressing of white grapes because the rasp facilitates the drainage of the must during pressing. In this regard, it is possible to rely on the GRIFO crushers available in both manual and electric versions, painted or in stainless steel.

CRUCHER: crushes the grapes through the compression exerted by the rollers that rotate in opposite directions. Used primarily for the pressing of white grapes because the rasp facilitates the drainage of the must during pressing. In this regard, it is possible to rely on the GRIFO crushers available in both manual and electric versions, painted or in stainless steel.

FILTER: A system for the clarification of wine or the must by mechanically separating the particles in suspension through a filter substrate. GRIFO plate filters are made of stainless steel or enamelled steel and are equipped with linear nylon plates (or noryl on request, for special applications). For the wineries, we propose the 40×40 filters which can be produced in different versions as needed.

FILTER: A system for the clarification of wine or the must by mechanically separating the particles in suspension through a filter substrate. GRIFO plate filters are made of stainless steel or enamelled steel and are equipped with linear nylon plates (or noryl on request, for special applications). For the wineries, we propose the 40×40 filters which can be produced in different versions as needed.

The evolution of wine-making machines

The various stages of vinification have undergone constant evolution over the centuries. Especially since the eighteenth century, with the introduction of the first forms of machinery, the wine industry saw a strong acceleration. In Italy, the manufacturers of oenological machines were mainly concentrated in Piemonte, Veneto and Emilia Romagna. In the period between the two great wars, there were over 50 manufacturers of crushers and 95 manufacturers of presses in Italy.

Crushers

In the nineteenth century, with the introduction of the first mechanical crushers, this practice became faster. Made primarily of wood, they consisted of two space rollers rotating in opposite directions that crushed the bunches and turned the grapes into must.

In the following years, the use of wood was gradually abandoned in favor of iron and cast-iron for the rollers and metal sheets for the hoppers.

On a qualitative level, a further important technological improvement came from crushing-sweepers, machines that, besides crushing the clusters, are able to separate and remove the stalks. All this thanks to a cylindrical cage within which a shaft rotates, with numerous spools disposed in a helical way which capture and expel the stems.

Once operated manually, all crushers later became automated.

Presses

The base structure of the press has not changed much in the centuries: a must collection basin (first of wood then of cast iron and sheet metal) surmounted by a cylindrical cage, made of wood strips, containing the pomace and a central threaded shaft with a rotating head that causes the pressure through a series of wooden plates.

What has evolved is the pressing mechanism applied to the base structure. The star arms (which involved a considerable physical effort) were replaced by a continuous screw system.

Subsequently, the “Mabille” system was introduced, conceived by French brothers Mabille, which allowed for greater pressure with less effort. The principle consists in the transformation of the alternating motion of a lever, driven by a single man, in the circular motion of the head, with the possibility of one, two or in some cases three different pressing speeds.

Lastly, in the twentieth century, the hydraulic pressure press was introduced, enabling the use of pressesof great sizes, suitable for large wineries.

Pieces of history

-

Small stainless-steel fruit crusher by hand cod. PIP

Read more -

Small stainless-steel fruit crusher by electric motor cod. PIPMO

Read more -

Big stainless-steel fruit crusher by hand cod. PIG

Read more -

Big stainless-steel fruit crusher by electric motor cod. PIGMO

Read more -

Mill for fruit cod. AM1

Read more -

Destoner by electric motor with 2 stainless-steel basket cod. DENS

Read more -

Stainless-steel destoner by electric motor with 2 stainless-steel basket cod. DENI

Read more -

Sheller for pomegranate by electric motor cod. SM

Read more -

Stainless-steel sheller for pomegranate by electric motor cod. SMI

Read more -

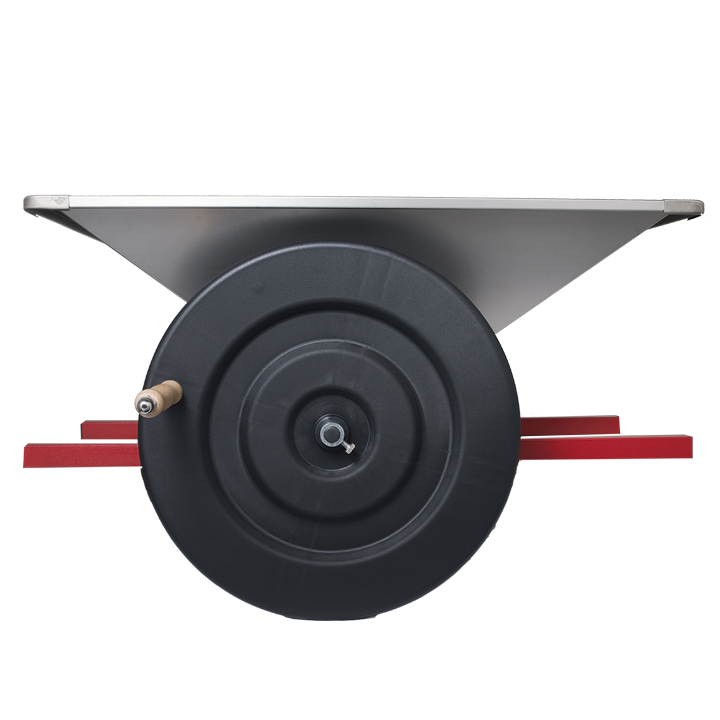

On stand for “Grape crusher and stalk remover – destoner – sheller”

Read more

cod. CAV -

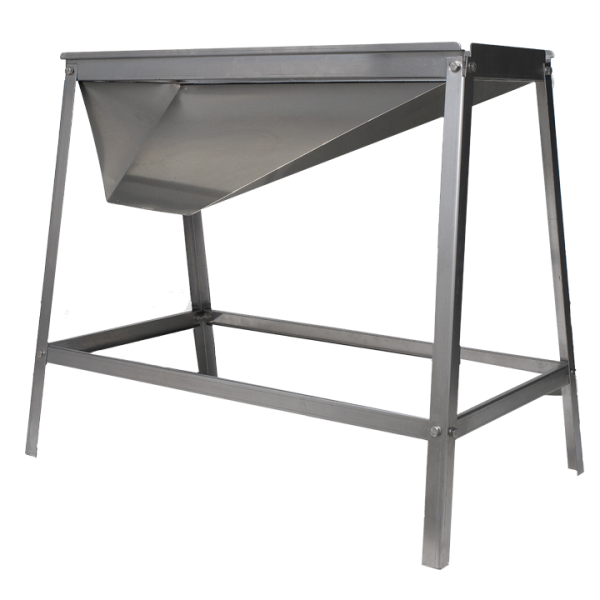

Stainless-steel on stand for “Grape crusher and stalk remover – destoner – shellers”

Read more

cod. CAVI -

Hydro press PEW20 cod. PEW20

Read more

Wine and christianity

Wine and christianity 1-

1-